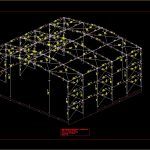

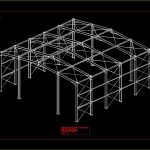

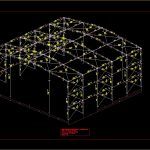

Structural Project Barn DWG Full Project for AutoCAD

Proyecto detallado of barn structure

Drawing labels, details, and other text information extracted from the CAD file (Translated from Portuguese):

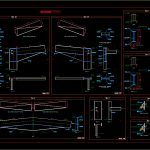

smaw rigging girder abutment abutment abutment abutment abutment abutment abutment a – a, cut c – c, plate, cut, base plate, side view, anchor bolts, anchor to the center of the plate, shed with welded connections , oval bore, round, cross section, oval hole detail, d – d cut, welded connections in metallic structure, standard :, materials :, definitions for welds in angle :, – side of the cord: it is the smaller of the two sides located in the melting faces of the largest triangle that can, – effective length of the weld bead: is equal to the total length of the weld with dimensions, constructive arrangements :, – the welded parts are not of tubular section. total or partial penetration is equal to its length, – in total penetration welds, the effective throat is equal to the smaller thickness of the joined parts, – in partial penetration welds, the minimum thickness of the effective throat complies with the values in the following table: , smaller and thickness of the parts to be joined, minimum squeeze thickness, effective – the effective throat thickness of the partial penetration welds is determined according to – the minimum side size of an angle weld meets the values in the following table: minimum size of the side of a weld, angle welding, executed in a single pass, – the maximum size of the side of an angle weld along the edges of welded parts, thickness of the material, effective weld. in addition, the effective length of an angle weld exposed to any, the cord surrounding the corners, with the same cord size, the surfaces on which the addition metal shall be deposited shall be smooth, uniform, and free of cracks and other discontinuities that would affect the quality or strength of the weld. the surfaces to be welded and the surfaces adjacent to a weld shall also be free of blades, scales, loose or adhered oxide, slag, rust, moisture, oil, grease and the like, foreign materials that prevent proper welding or produce – the method used to check the strength of the weld beads is that in which the – the effective area of a weld bead is equal to the product of the actual length of the bead by – in the verification of the weld bead resistance of the weld beads was considered a minimum request of welds, strength class, execution, type, side, length of strands, in workshop, fillet, bevelled top, simple, on-site, simple with region no, bevel wide, sheets, material, quantity, dimensions, weight, stiffeners, total, angles, description, length, tie rod anchors, screw elements, nuts, washers, base plates and, elements, references and symbology, examination ‘, method of representation of welds, the following scheme of representation of a weld :, references :, s: depth of the bevel. in angle welds, is the side of the weld bead., l: effective length of the weld bead, d: supplementary data. in general, the series of electrodes to be used and the pre-qualified welding process, the information related to the side of the welded connection to which the arrow points, lies below the reference line, whereas for the opposite side, indicated above the reference line :, where :, designation, illustration, symbol, fillet welding, single-bevel top solder, dual-bevel top solder, single-bevel top weld with root bevel wide, single-angle and single-angle combined weld, single-edged single-edged weld with curved side

Raw text data extracted from CAD file:

| Language | Portuguese |

| Drawing Type | Full Project |

| Category | Retail |

| Additional Screenshots |

|

| File Type | dwg |

| Materials | Other |

| Measurement Units | Metric |

| Footprint Area | |

| Building Features | |

| Tags | armazenamento, autocad, barn, celeiro, comercial, commercial, DWG, full, grange, Project, proyecto, scheune, storage, structural, structure, warehouse |