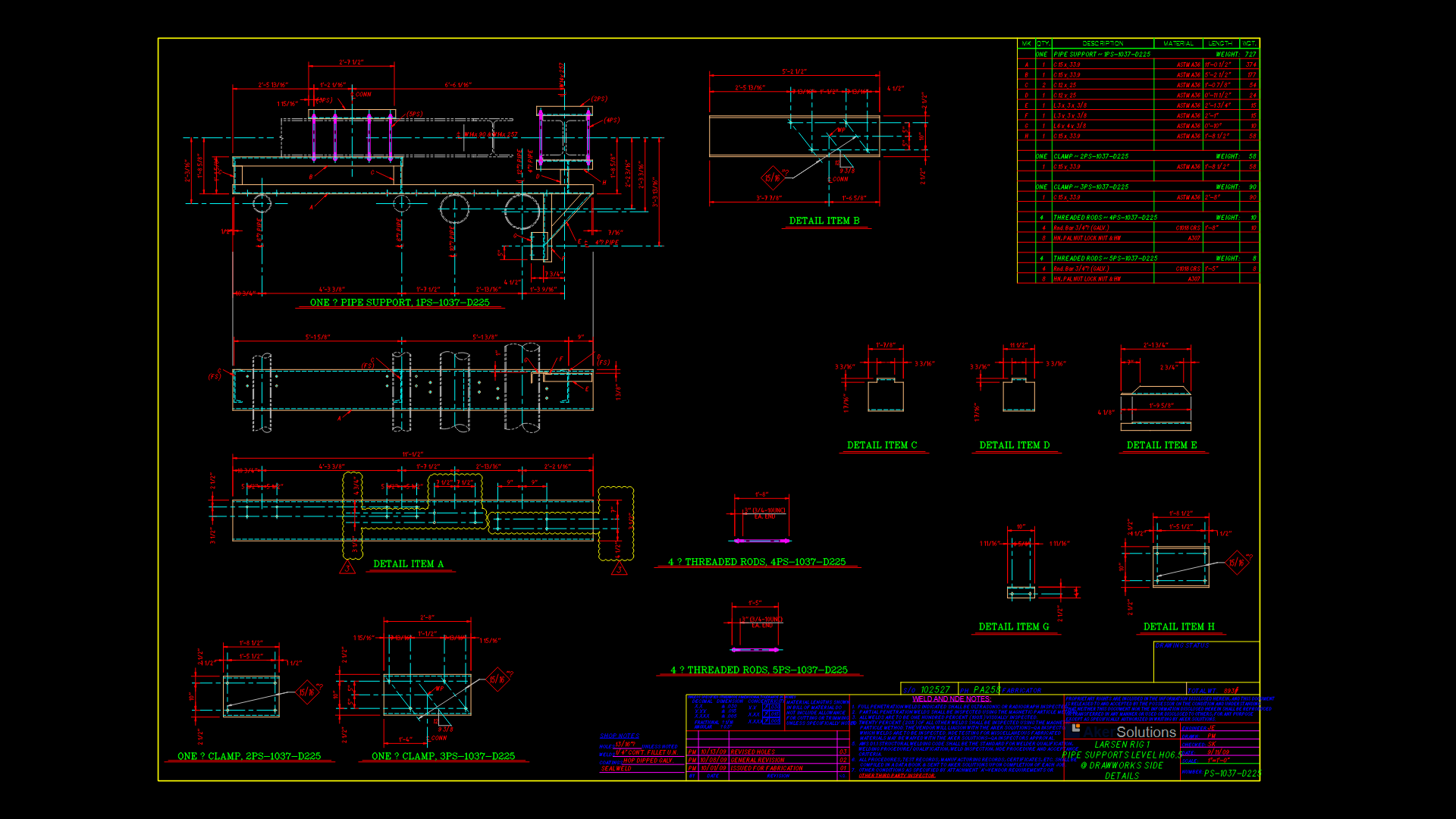

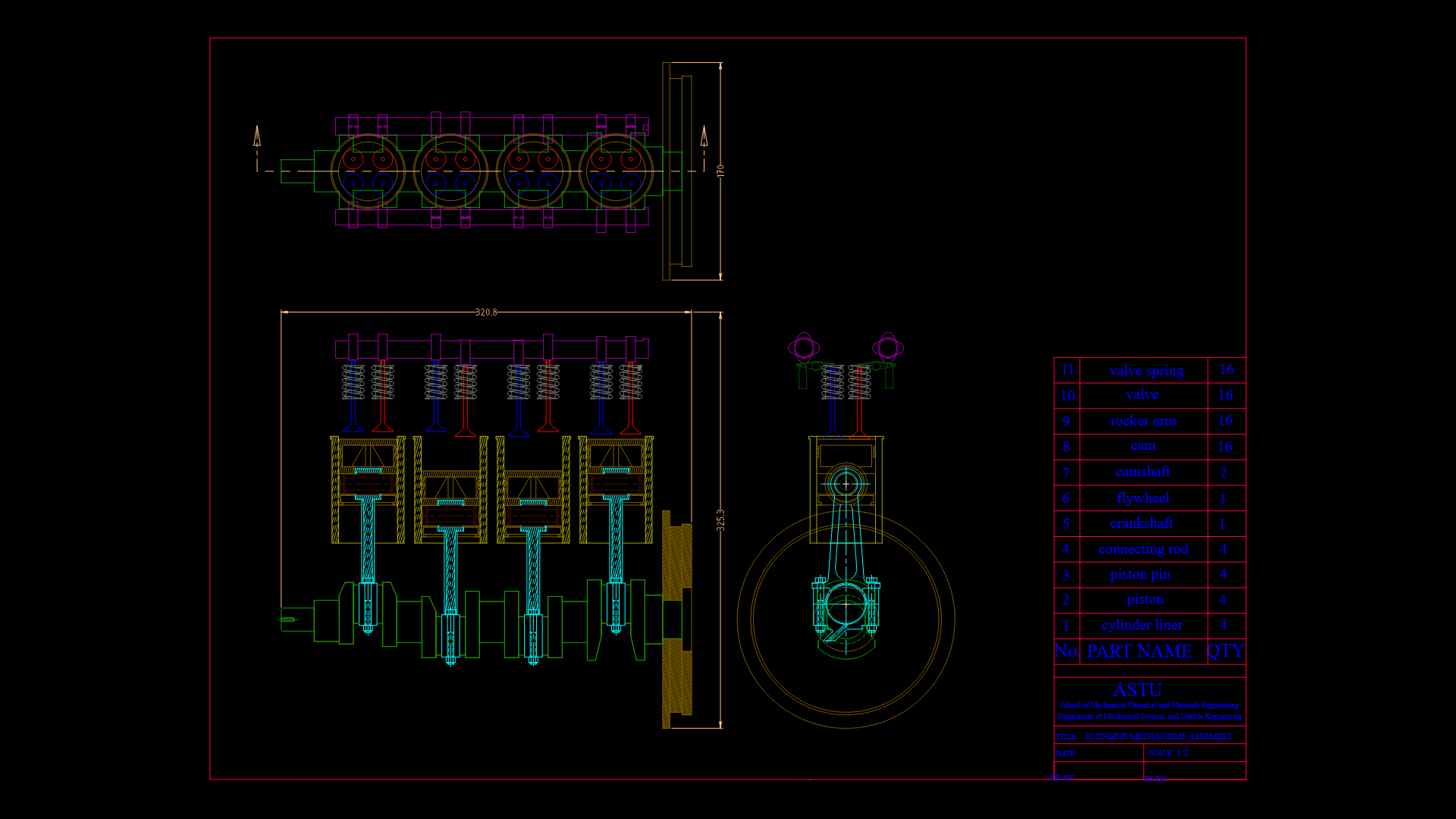

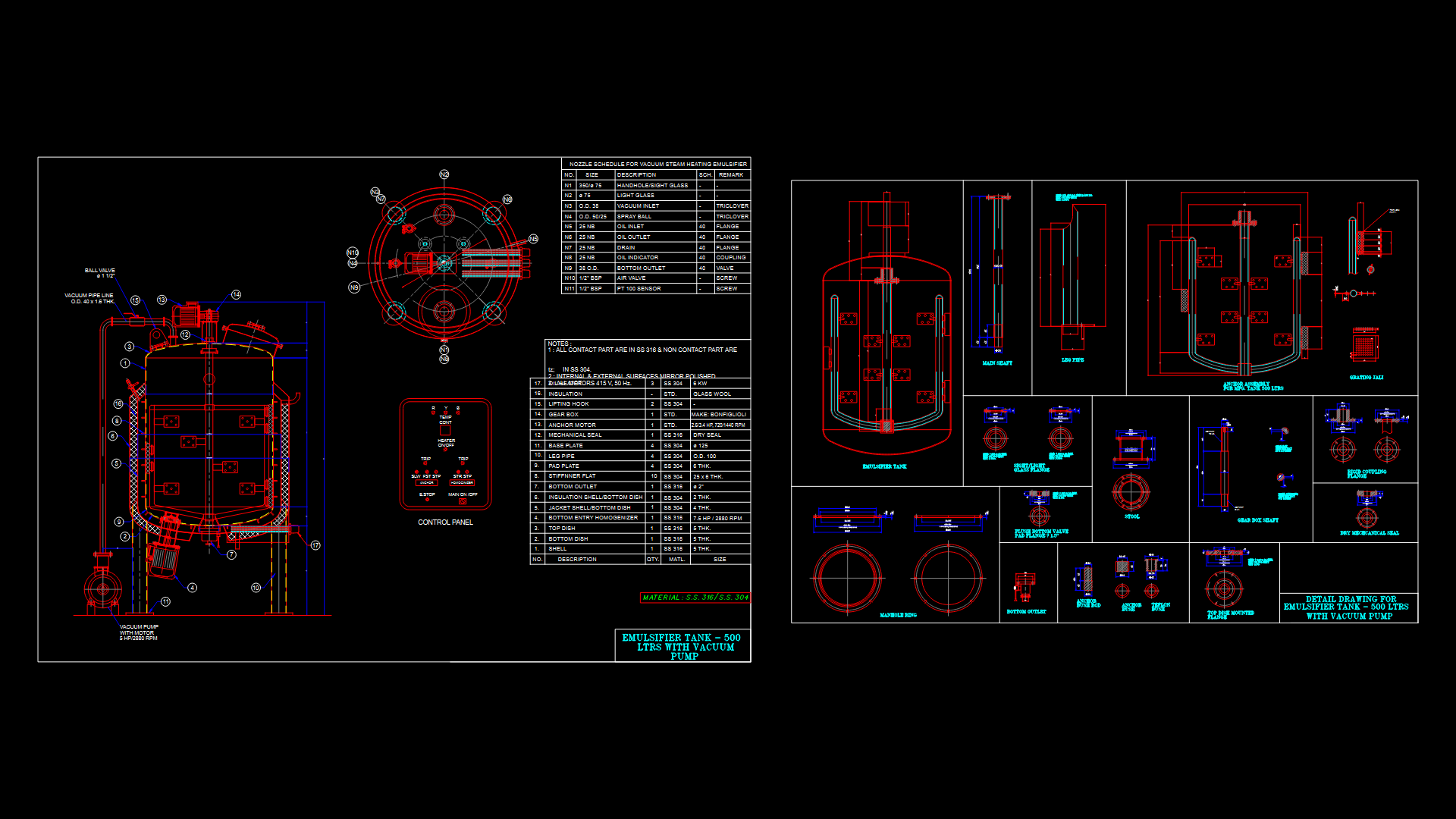

500L Vacuum-Jacketed Emulsifier Tank Assembly Detail Drawing

This detailed engineering drawing depicts a 500-liter stainless steel emulsifier tank with vacuum heating system for pharmaceutical processing. The vessel features an 850mm ID inner shell (5mm thick SS316) surrounded by a 940mm ID jacketed shell (4mm thick SS304) and 1050mm ID insulation layer (2mm thick SS304). The assembly includes a bottom-entry homogenizer with 7.5HP/2880RPM motor, 2.6/3.4HP anchor agitator with dual-speed (720/1440RPM) capability, and mechanical dry seal. The tank incorporates multiple process connections: 38mm OD bottom outlet valve, oil inlet/outlet flanges (25NB), vacuum inlet triclover fitting, handhole/sight glass (350/75mm), spray ball, and PT100 temperature sensor. Notable components include a 5HP vacuum pump, 6kW oil heater, control panel with temperature controller, and four SS304 support legs (100mm OD) with base plates. All product-contact surfaces are SS316 with mirror polish finish, while non-contact parts are SS304, adhering to pharmaceutical GMP standards.

| Language | English |

| Drawing Type | Detail |

| Category | Industrial |

| Additional Screenshots | |

| File Type | dwg |

| Materials | Steel |

| Measurement Units | Metric |

| Footprint Area | 1 - 9 m² (10.8 - 96.9 ft²) |

| Building Features | |

| Tags | emulsifier tank, GMP standards, homogenizer, pharmaceutical equipment, process equipment, stainless steel vessel, vacuum jacketed |