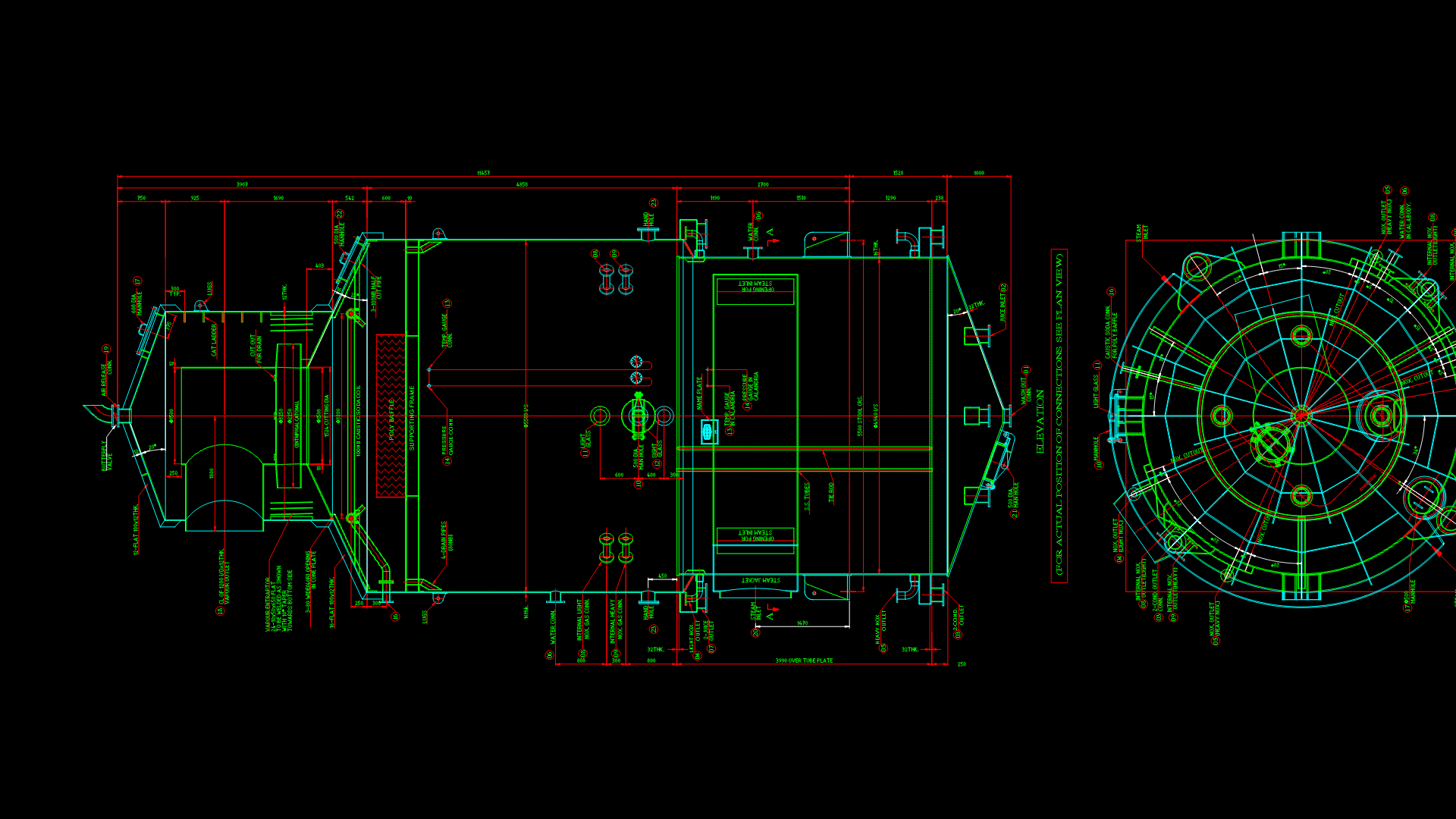

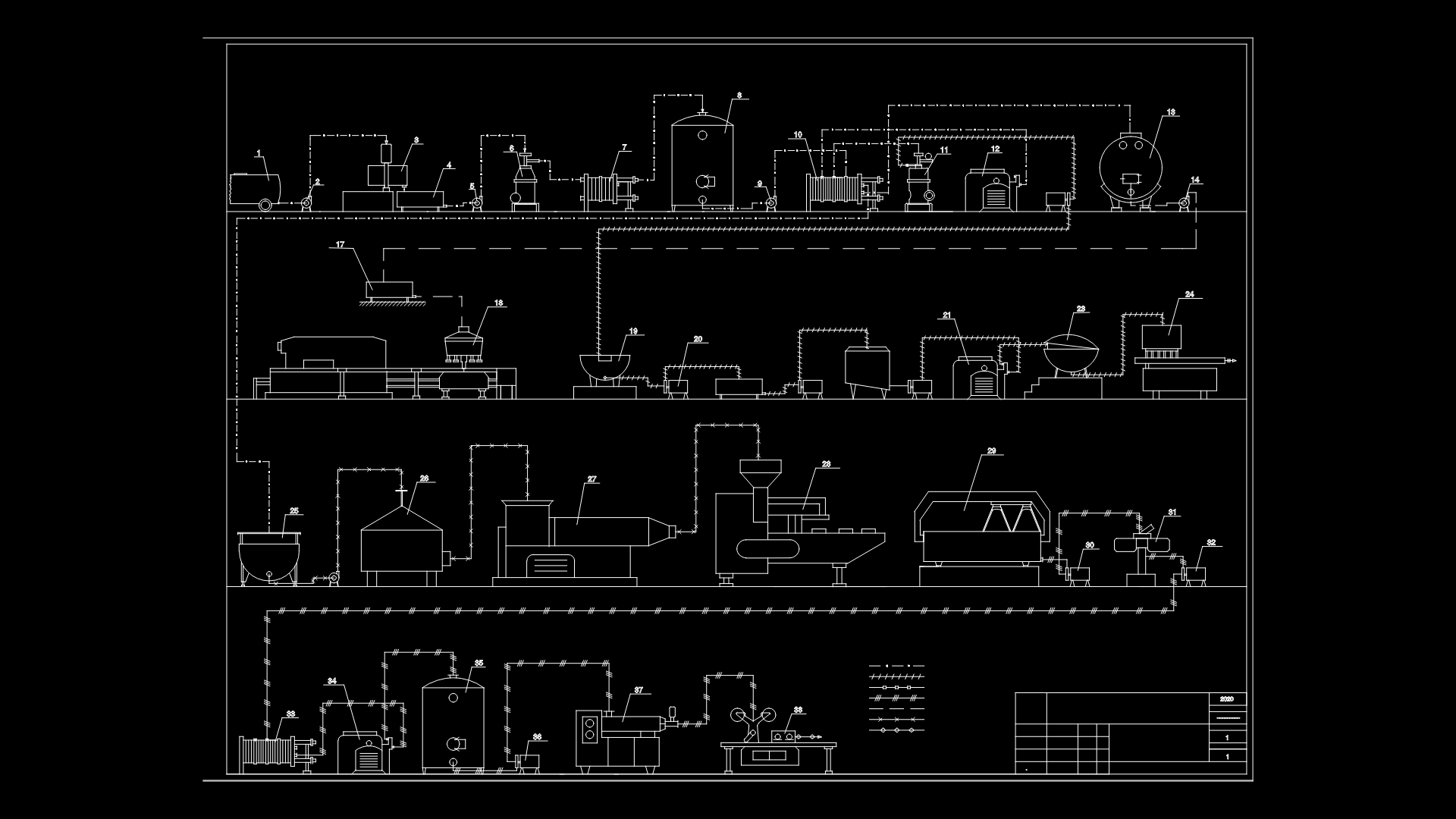

Industrial Process Flow Elevation Drawing with Multi-Stage Equipment layout

This detailed elevation drawing illustrates a comprehensive industrial processing line with multiple equipment stages arranged in sequential workflow zones. This layout features several processing vessels, storage tanks, heat exchangers, and specialized machinery interconnected through a systematic process flow. Key components include pressure vessels (items 6, 16, 36), multiple storage tanks with agitators, heat transfer equipment, and material handling systems. The processing line appears to incorporate both batch and continuous flow operations with approximately 32 numbered equipment items distributed across four distinct production stages. The drawing uses standard industrial P&ID symbology with equipment interconnections clearly delineated. Notable design considerations include adequate spacing between major equipment groups to allow for maintenance access and operational requirements. The overall arrangement optimizes vertical space utilization while maintaining logical process flow sequencing throughout the facility.

| Language | English |

| Drawing Type | Elevation |

| Category | Industrial |

| Additional Screenshots | |

| File Type | dwg |

| Materials | Steel |

| Measurement Units | Metric |

| Footprint Area | 500 - 999 m² (5382.0 - 10753.1 ft²) |

| Building Features | |

| Tags | Industrial Equipment, manufacturing layout, P&ID, plant design, process engineering, process flow, production line |