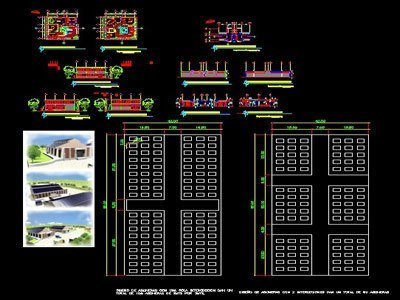

Processing Plant DWG Full Project for AutoCAD

Chicken processing plant ;and all buildings related to the project

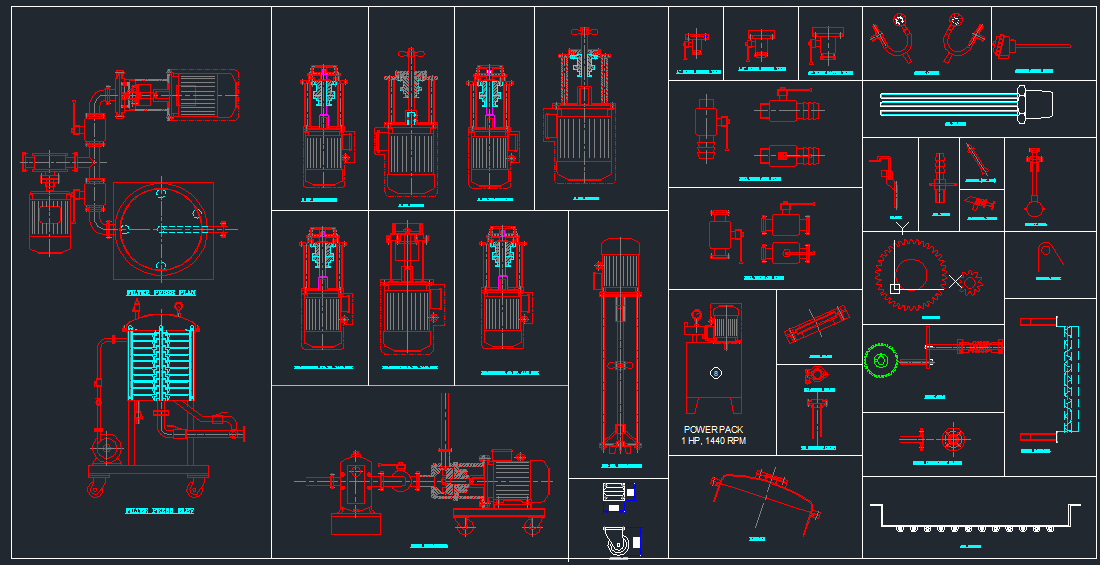

Drawing labels, details, and other text information extracted from the CAD file:

graphic scale :, scale :, metal roofing panel, t. o. bond beam, steel column, wall with insulation, scale, metal roof panel, top of slab, continue from, left, width, inlet, scum, water level, c.i, manhole cover, out let, sludge, rcc, beam, standing wall, outlet, iron foot step, section b-b, arrangement of steel, bars in roof slab, stone metal, honeycomb wall, description, specified, compressive strength, for non reinforced cast in, place concrete, suspended slabs and walls, for footings,pedestals,columns,, grade beams,slab on grade,, general notes:, foundation formation level shall be fully compacted before placing, lean concrete., all slab on grade, beams and footings shall have no horizontal construction, joints. stops in concrete work must be made at middle third of span with, vertical joints., reinforcing steel bars shall be deformed billet steel bars conforming to, backfill between excavation and footings shall be compacted to a, foundation reinforcement table, type, palin cocrete, reinf. concrete, short steel, long steel, main, capo., rings, section, steel, nicks, columns, down steel, ground beam reinforcement table, up steel, lean concrete, c section, c section, of roof, base plate, bottom of steel, leveling grout, slope, frame elevation, pre-fin. metal ridge flashing, pre-fin. non-insulated metal roof panel, steel purlins, steel beam, with wire mesh reinfo., plan, roof, gri., mix., n. g.level, roof slab reinforcement table, notes, str., sec: a-a, for all concrete above ground lev type i, structural engineer., architectural and mechanical drawings. openings not shown on structural,, drawings shall be installed only after the approval of the, the pouring of concrete., submitted to the engineer for approval., the locations of all construction joints shall be shown on shop dwgs, all reinforcement shall be continued across construction joints., perpendicular to the main reinforcement., at the tops of footings or floor slabs, joints shall be placed, columns shall be at the underside of floors,slabs,beams,or girders and, to twice the width of the beam. construction joints in walls and, point,in which case the joint in the girder shall be offset a distance equal, middle one third of the spans unless a beam intersects a girder at this, construction joints,any stops in concrete work must be located near the, all slabs,joists,beams,girders and footings shall have no horizontal, poured before pouring beams and slabs adjacent to those columns., there shall be a delay of at least two hours after columns have been, on manufacturers specs., drawings for approval which shall be based, considred part of this contract.the contractor should provide shop, structural concrete notes, as follows:, – plean concrete fills,, concrete blinding and, all other concrete,, including foundations,, walls, solid slabs, joists, columns, all beams and, the portland cement to be used in the concrete mix shall, be as follows:, labeled, supported and spaced in forms and secured in, place in accordance with the procedures and requirements, ” requirements, steel sizes, spacing, placement, construction joints, curbs,, depressions etc. shall be submitted to the supervising engineer, for review and approval prior to fabrication., in the drawings., panels and tied securely., be detailed as follows:, a. the under side of all footings and concrete placed against, reinforcing, unless noted otherwise., additional reinforcing requirements of pads. these pads are, of the gross concrete area., immediately prior to pouring new concrete., wall , slab and footing openings., see also applicable specifications sections on concrete., except as otherwise shown all underground structures, in contact with soil should receive two coats bituminous paint, as specified., building elevation, fin. flr. line, top of sidewalk, top of parapet, top of roof slab, building section, wall detail, air flow, metal screw, wood frame, inside, outside, aluminum backdraft damper, varies, fixed aluminum exhaust louver to fit opening, inside clear opening, not, wall mtd. exhaust fan detail, wall, fire extinguisher holder mounting detail, n.t.s., mtg. detail of portable fire extinguisher, pressure gauge, hose, blow pipe, cylinder, fin. floor line, stiffeners, fire extinguisher, ffl, type a, roof slab, section in wall, section in reinforcement wall, section colum, offal pump, packing table, packing horn, offal separator, recirculation pump, blood pump, blood collecting tank, vaccume plant, vaccume reservoir, collecting tank, air compressor, no., pos no, item, legend, el.drive unit, collecting tray, over head cooling conveyor, frequency converter, set of guide rails, bird discharger, single guide rail, weighing bridge, drop -off station, aut.opening machine, aut.eviscerator, aut.vent cutter, evisceration trough, giblet transport channels, gizzard cutti

Raw text data extracted from CAD file:

| Language | English |

| Drawing Type | Full Project |

| Category | Industrial |

| Additional Screenshots |

|

| File Type | dwg |

| Materials | Aluminum, Concrete, Glass, Masonry, Steel, Wood, Other |

| Measurement Units | Imperial |

| Footprint Area | |

| Building Features | Deck / Patio |

| Tags | autocad, buildings, DWG, factory, full, industrial building, plant, processing, Project, related |