Specification Installation Losacero DWG Detail for AutoCAD

SPECIFICATION INSTALLATION LOSACERO . FIRST PART ; FOLLOWING DETAILS AND MORE SPECIFICATIONS OF INSTALLATION

Drawing labels, details, and other text information extracted from the CAD file (Translated from Spanish):

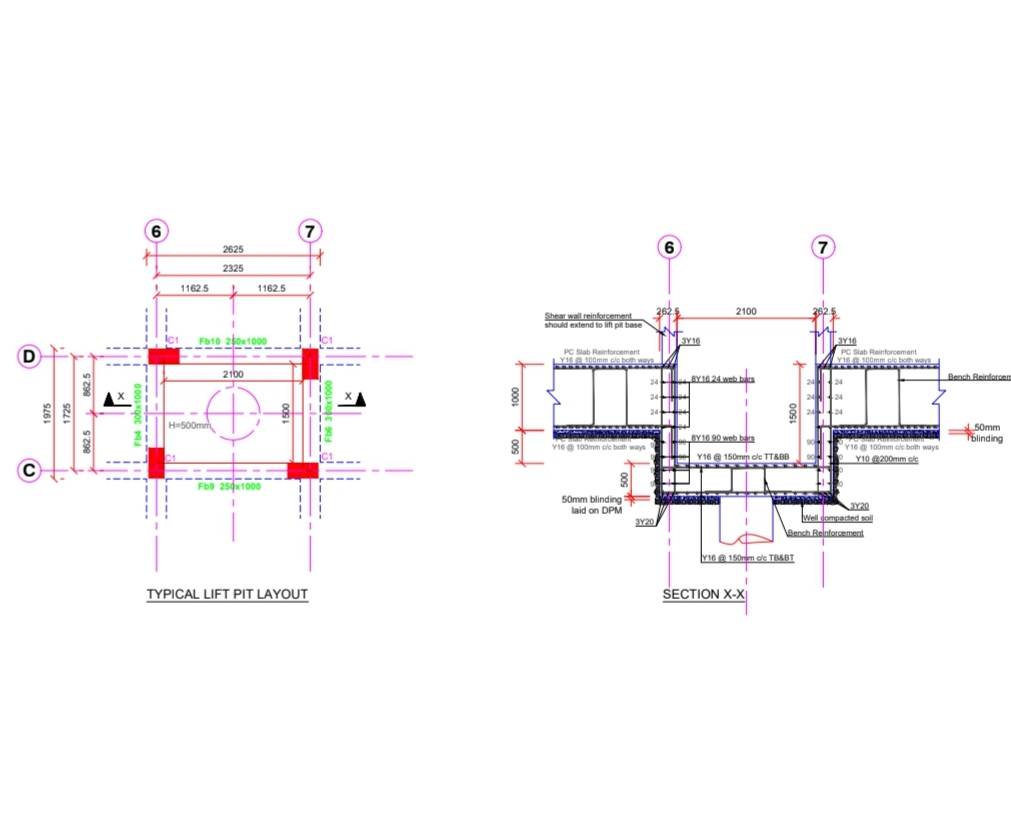

waterproofing, unibase mesh, lime, the seal, false acoustic ceiling, welded Mesh, ipr beam, rooftop, welded Mesh, the seal, lime, ipr beam, false acoustic ceiling, mortar warped, prop., tezontle stuffing, crystal clear mm, curtain rack, post, eps, crystal clear mm, curtain rack, reinforced concrete ceiling, dropper, interior wall panel, grout, prop thickness, brushed finish, mortar flange, with brick lid, cm brick, mortar prop, to receive brickwork, parapet, corev folder, eps frame, red brick wall annealed, the seal, every valley, bolt on, concrete, losacero galvadeck cal., imsa section lime., the seal, concrete, lock metal, lock metal, mesh, draft:, Location:, arq. responsable:, graphic scale, dimensions in meters, localization map, enrollment:, owner:, place date:, lamina galvamet cal., molding, section steel beam, connectors, the joints between two blades should not overlap when there are connecting connectors to enable them to directly weld the support beam. in addition a frame must be placed to avoid concrete leakage., note:, ipe to pillar attachment bracket, haircol collaborating sheet, ipe, welding made in workshop, placed on site, ordinary screws, section, steel cover, concrete slab, secondary beam, acoustic panel, n., wire suspender, primary beam, channel guide, the seal, cold rolled, n., channel guide, the seal, cold rolled, urban nucleus in the metropolitan area of tarimbaro, town hall, of April, variable, flat:, municipality of tarimbaro, gaona balpuesta miguel angel, handling storage: ensure that the transport of the die cut sheet comes in closed trucks covered with impermeable tarpaulins. the ingasa lamina will be stored indoors. in a ventilated dry place. on bar pallets. Do not place directly on the floor. the support of the plates of the plates of the ingasa lamina will be made on a surface on the distance between the supports will be of mts. for packages composed of plates. use the number of people suitable for the correct discharge of the product ingasa to avoid that the blade is scratched be struck. when the blade is maneuvered from another place grasp the ends in a non horizontal horizontal way. for manual lifting the plates must be raised by means of ropes in the form of a cross securing the ends by a hook. the staff must wear leather gloves. who are working on the deck use shoes with rubber soles. tables should be placed at the time of transit on the sheet. do not use polyethylene plastics to cover the packages of sheets. do not store acidic solvents such as plaster cement together with ingasa products. at the conclusion of the installation of the check that the cover is clean free of objects avoid to the maximum the transit on the cover. clean the cover every month. an anticorrosive paint layer should be applied to the lamina of the opposite area to melt., general: concrete must have a compressive strength the days of not using accelerating setting additives containing sodium chlorides. a seam with galvanized wire should be made at the longitudinal joint of the sheet. this operation will be done every mts. using the punch. detail the thickness of the concrete will be cms above the level of the ridge. the concrete coating will be cms. for the splice of foils on a beam it is possible to use welding points of self-tapping screw nail firing. the joints between two blades should not overlap when there are shear connectors to allow the beam to be directly welded. In addition, you should place a cover trim to prevent concrete leakage. Connections of the smaller pipes may be embedded within the concrete of the slab. the larger pipes will pass under the slabs held by clamps. the different types of moldings will be of galvanized finish applied according to the corresponding detail to see details of the disassembling should be made the days when the concrete has arrived one of the capacity of its resistance the compression. the entire installation of the floor will be strictly supervised which will verify the applicability of the same., flat slabs, Specifications

Raw text data extracted from CAD file:

| Language | Spanish |

| Drawing Type | Detail |

| Category | Construction Details & Systems |

| Additional Screenshots |

|

| File Type | dwg |

| Materials | Concrete, Glass, Plastic, Steel, Other |

| Measurement Units | |

| Footprint Area | |

| Building Features | Deck / Patio |

| Tags | autocad, DETAIL, details, DWG, installation, losacero, part, slabs, specification, specifications, stahlrahmen, stahlträger, steel, steel beam, steel frame, structure en acier |