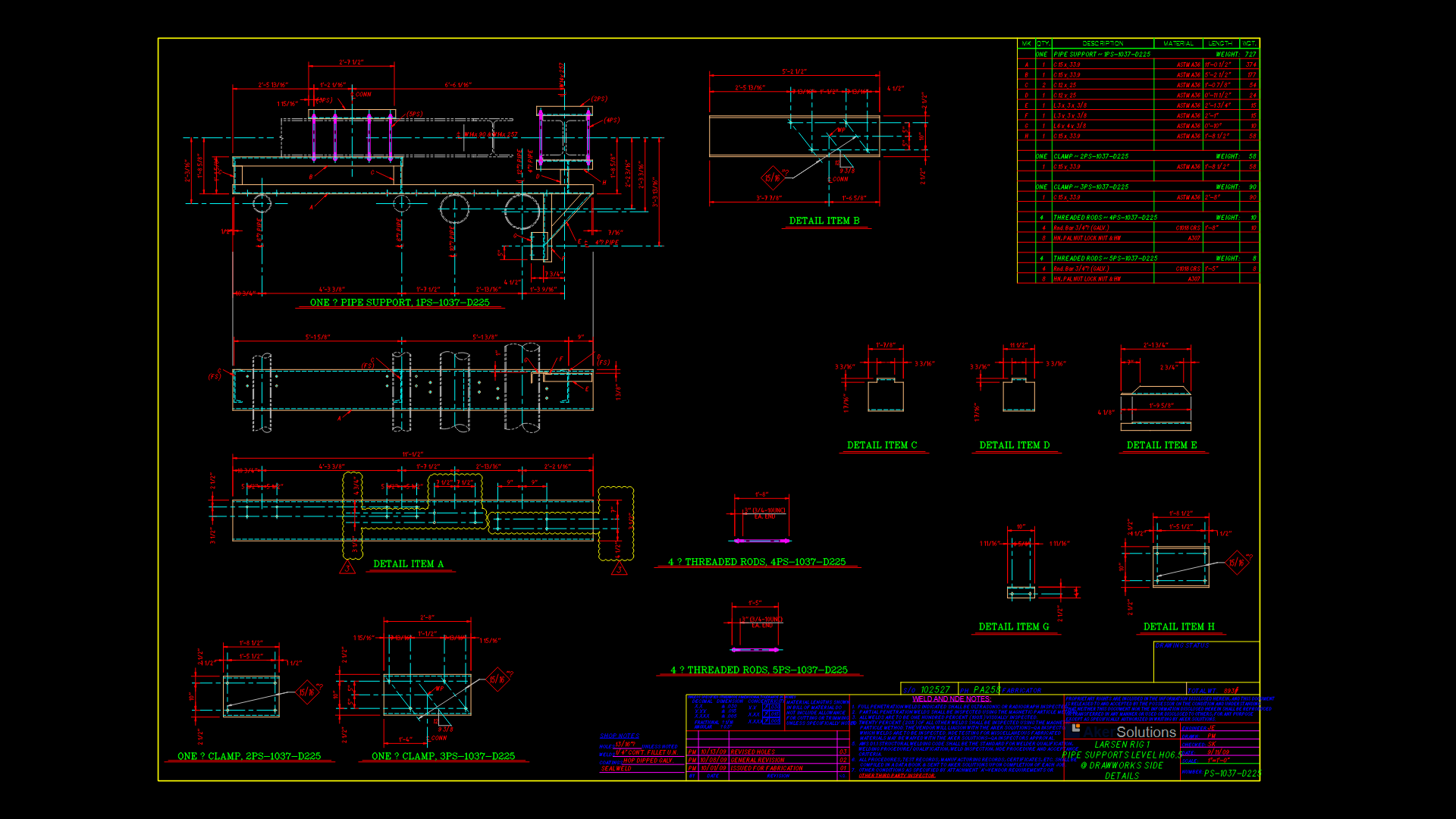

Mining Slurry Rubber Pipe Bend Detail Drawing for High-Pressure Applications

Standard Rubber Pipe Bends for Mining Slurry Systems

This technical drawing details standardized rubber bend fittings for mineral slurry transportation systems operating at high pressure (10 kgf/cm²). The drawing illustrates five distinct bend angles: 90°, 60°, 45°, 30°, and 22.5° with comprehensive dimensional specifications.

Key Components:

– Flanged rubber bends designed specifically for mineral slurry applications

– Available diameters: 3″ through 26″ (76.2mm – 660.4mm)

– All fittings designed to ASME B16.5 flange specifications

– Operating pressure rated at 10 kgf/cm² (approximately 142 PSI)

The drawing includes a detailed dimensional table with parameters for each bend angle and diameter combination, showing values for:

– A: Center-to-face dimension

– C: Bend radius measurements for each angle variation

– D: Flange face-to-face measurements

– R: Bend radius

Manufacturing Note: All fabrication processes, materials, and testing requirements must conform to Vale standard ET-M-624, as referenced in note #4. This document represents Vale’s standardized components for the Conceição plant ROM 2014 adaptation project, drawing number DT-1000CC-T-12311.

| Language | Portuguese |

| Drawing Type | Detail |

| Category | Industrial |

| Additional Screenshots | |

| File Type | dwg |

| Materials | Steel |

| Measurement Units | Metric |

| Footprint Area | N/A |

| Building Features | |

| Tags | ASME B16.5, flanged connections, high-pressure fittings, mineral processing, mining slurry pipe, rubber pipe bends, Vale standard |