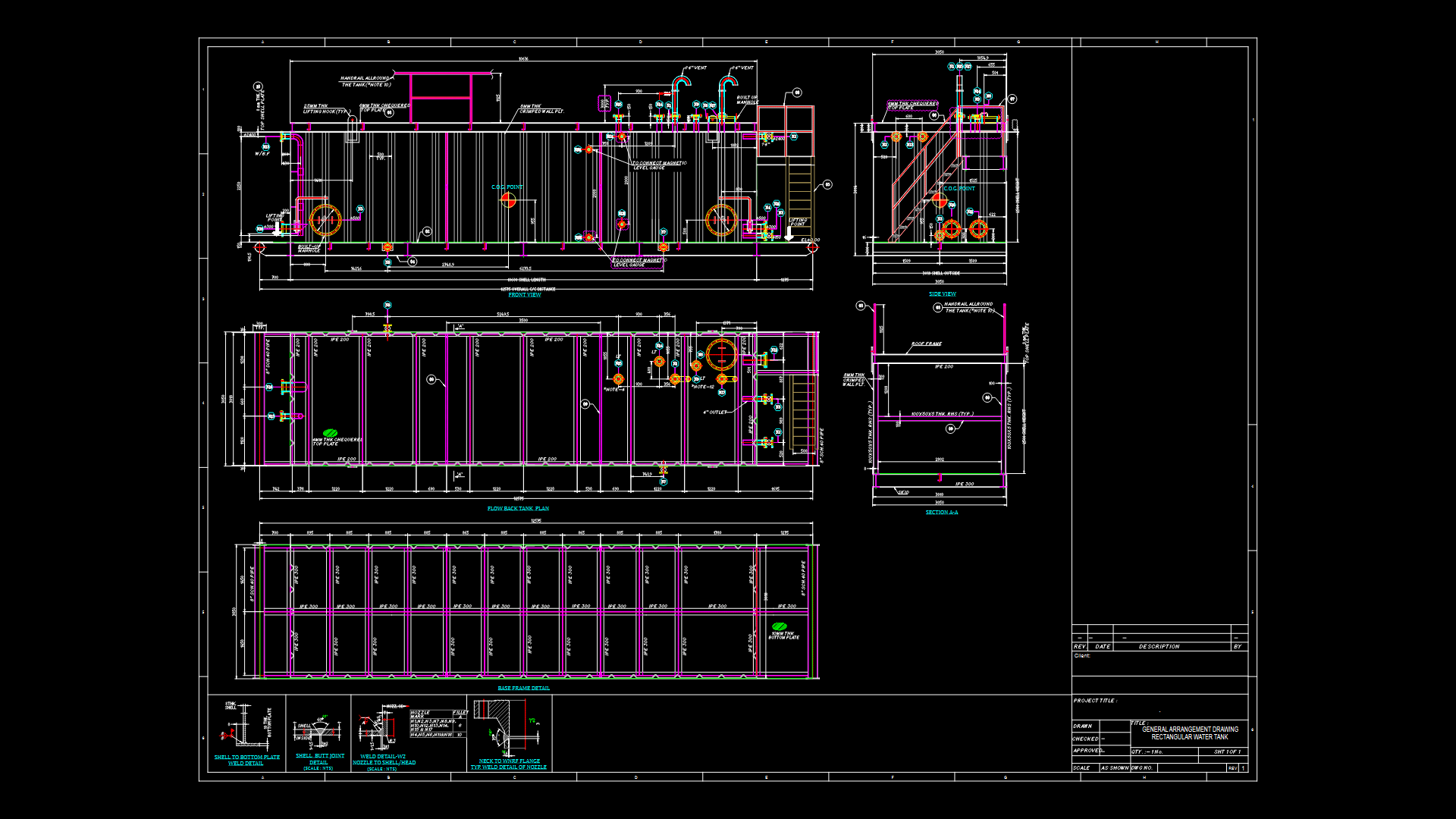

Oil Vessel Details DWG Plan for AutoCAD

Plans and sections of a Heavy Oil Separator Tank. Cortes Tank with designations and bounded.

Drawing labels, details, and other text information extracted from the CAD file:

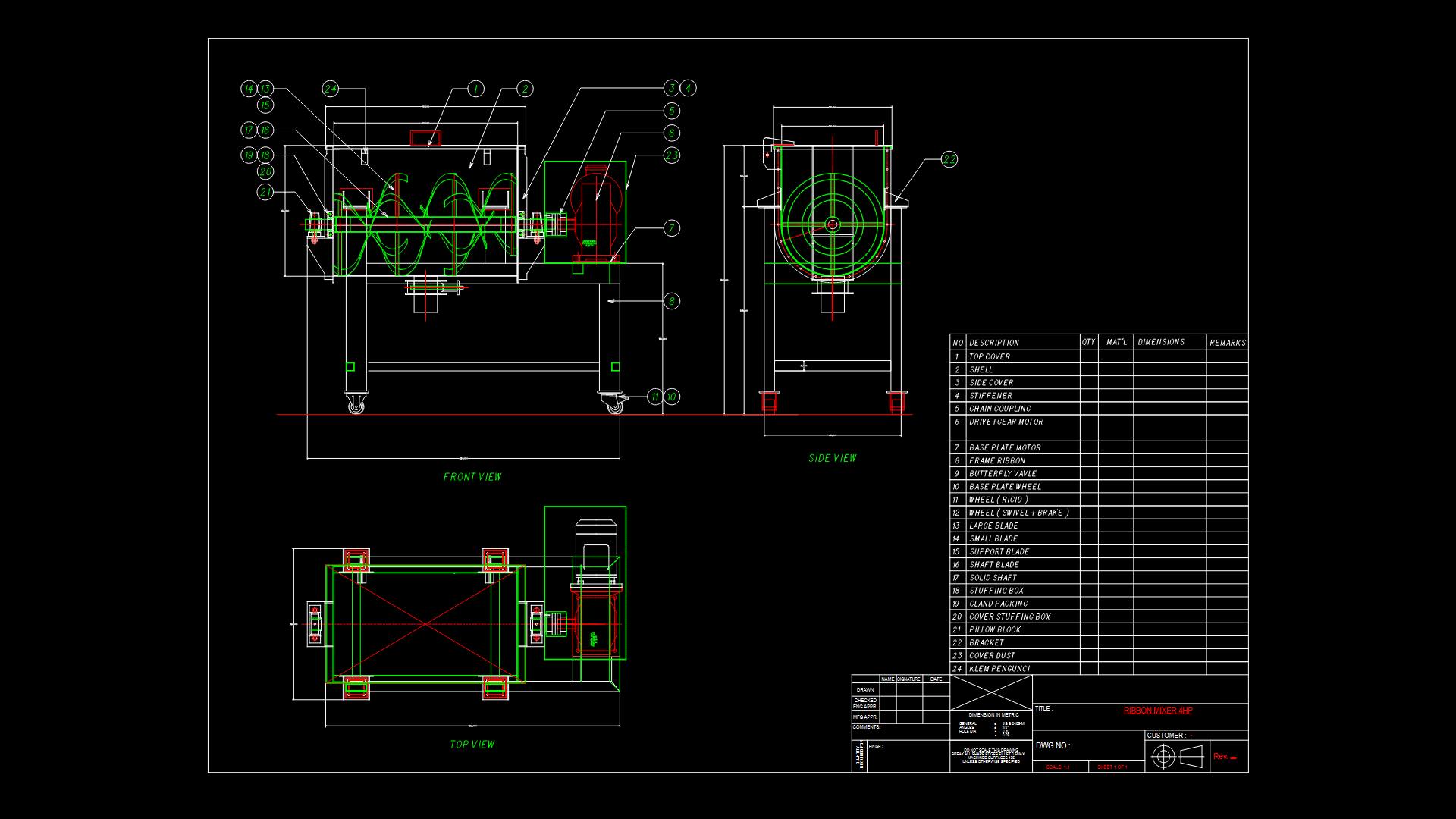

file no., discipline, title, area, scale, notes:, appd., no., date, chkd., drawing number:, reference drawings, permit stamp:, system coordinates:, xxx, xxxxxxxxx, xxxxxxxx, xxxxx, old dwg. name:, calgary, alberta, l.s.d., chk., revision, app’d., drn., rev., drawing number, engineering ltd., bower damberger rolseth, welding fittings:, uniones soldables, pl. refuerzos, reinf. plates:, materials, materiales, internals:, internos, bars:, varillas, shapes:, perfiles, gaskets:, empaques, couplings:, couplings, tuberia, pipe:, bridas, flanges:, soportes, supports:, heads:, cabezas, cuerpo, shell:, drawing no., section, pcv, lsl, lsh, fqi, lcv, old mariann revamp, group separator skid, piping sections, issued for construction, omitted for clarity, meters provers, daniel, not designed by b.d.r. eng. ltd. is only shown as a representation of what, it shall be the responsibility of the owner’s representative to verify, the location and status of any piping, electrical, equipment or buildings., the drawing may not be an accurate representation of the constructed facility., any changes not documented will not appear on the drawings and therefore, information forwarded to bower damberger rolseth engineering ltd. by, exists and must be verified by the owner., the owner’s field supervisors and or hired contractors., post construction notes, field weld, ecc. red, fixed saddle, t.o. steel, psv, plan view, slidding saddle, pipe supports to skid., manufacturer is to verify pipe support locations, match drill and bolt, removed for reassembly on site by others., system wherever possible., skid package., piping and other, skids and supports, studs and nuts, screwed fittings, – all instrumentation as described on the drawings and purchase orders., by the skid manufacturer :, – all valves are as per c.i.c.l. specification., and will be complete with armour channel to its location., instrument shall have a valved take-off from the supply header, – all instrumentation tubing is to be swagelok stainless steel. each, tubing, and tube fittings., – pipe, fittings, studs, nuts, gaskets, u-bolts, stainless steel, welded pipe joints., equipment, vessels, piping, gaskets, u-bolts, flanges, weld fittings, pipe, valves, general notes, – all prime, paint, internal coating and surface, preparation as per c.i.c.l. specifications., and rubber sleeve., group separator, piping details, not set, conc reducer bw, std., bonney forge, flange rf wn, pipe smls, vessel detail, elevation view, a-a view, near side, head a, typ., head b, baffle, internal, deflector, inlet, b-b view, insulation, inlet, sch std, gas outlet, water outlet, vent, drain, lit nozzle, deleted, mark, identifier, size, description, type, class, remarks, crude oil outlet, design conditions, hydro test press:, insulation:, test:, post weld heat treatment:, psi., minimun design metal temp., operating temperature:, operating pressure:, design temperature:, design pressure:, code:, psi, sample point, general notes:, spare, spiral wound, hydro test, nozzle position in vessel, nozzle dimension, nozzle rating, old nozzle name, new nozzle name, default orientation

Raw text data extracted from CAD file:

| Language | English |

| Drawing Type | Plan |

| Category | Industrial |

| Additional Screenshots |

|

| File Type | dwg |

| Materials | Steel, Other, N/A |

| Measurement Units | Metric |

| Footprint Area | |

| Building Features | |

| Tags | autocad, bounded, cortes, designations, details, DWG, factory, heavy, industrial building, oil, plan, plans, sections, separator, tank |