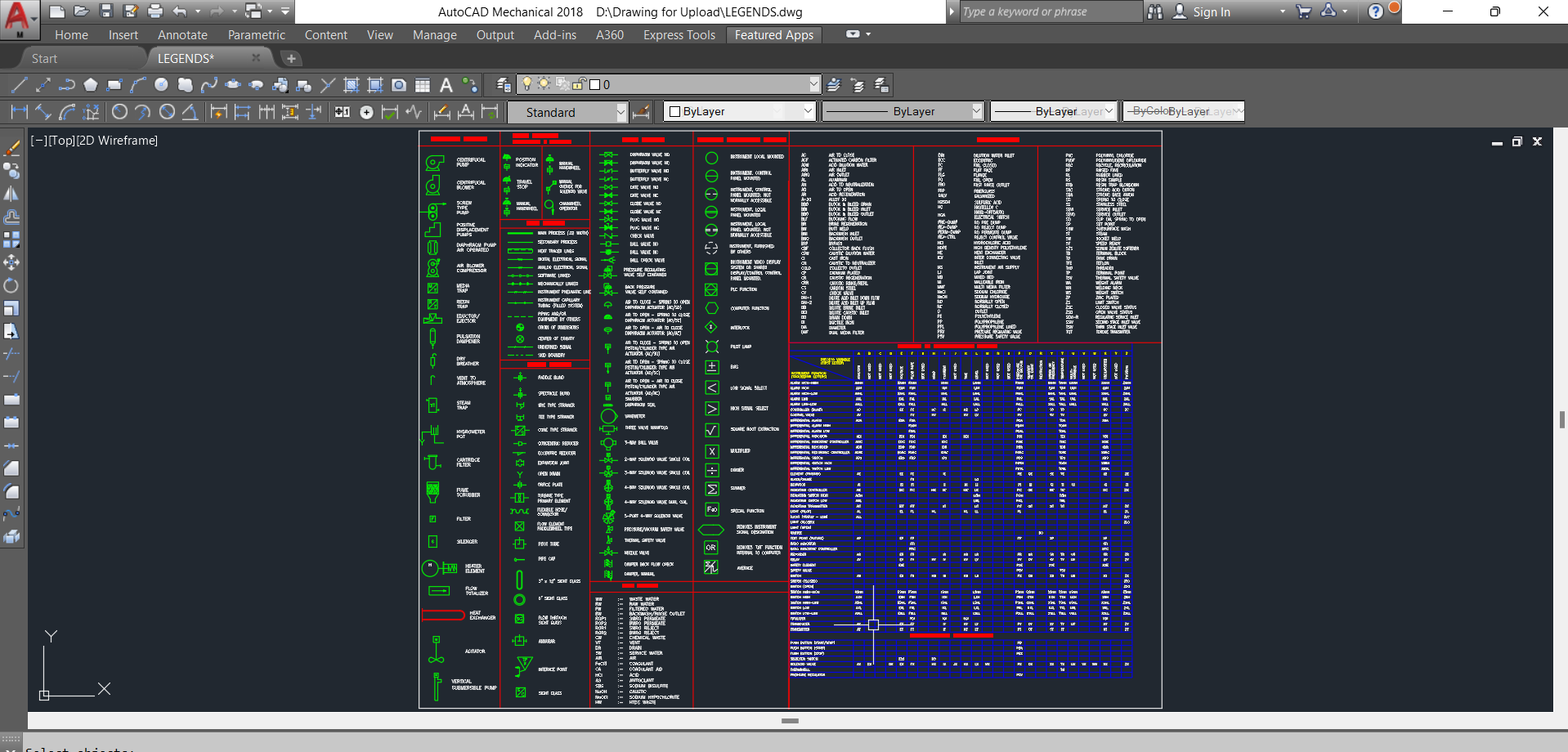

PACKED COLUMN WITH CONDENSOR

This drawing contains a detailed G.A. drawing with all parts detail drawing & complete Bill of material which helps to manufacture the column.(MOC -SS304 / SS316 / SS316L)

This drawing will helps a lot to manufacture the system,

The following are the specifications of the system

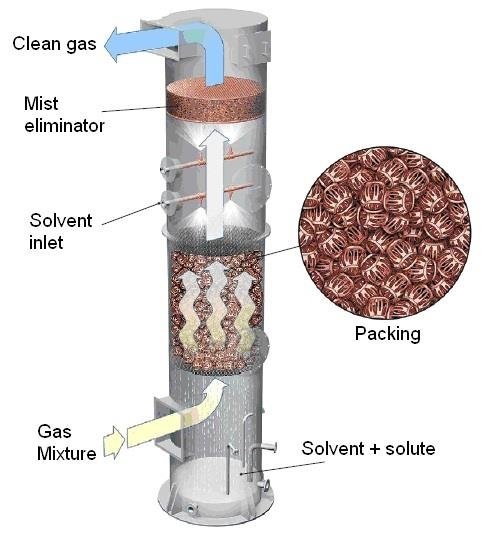

A packed column with a condenser is a common setup in various chemical and industrial processes, particularly in distillation and fractional distillation. This configuration is used to separate a mixture of different compounds or substances based on their boiling points. Here’s a brief overview of the components and their functions:

Packed Column:

The packed column is a vertical or inclined cylindrical vessel filled with a packing material, which could be materials like glass beads, metal rings, or structured packing. This packing provides a large surface area for vapor-liquid contact.

The purpose of the packed column is to facilitate the separation of the components within a mixture by allowing vapor to rise through the packing while coming into contact with the descending liquid phase. This contact promotes mass transfer between the vapor and liquid phases, enabling the separation process.

Condenser:

The condenser is typically located at the top of the packed column. It’s a heat exchanger that cools and condenses the vapor phase into a liquid.

The condensation process is essential because it allows the separated components with lower boiling points to return to the liquid phase, while the components with higher boiling points remain in the vapor phase. This separation is crucial for the desired product purification.

Here’s how the packed column with a condenser works in a distillation process:

The mixture to be separated is heated in a reboiler, typically located at the bottom of the column, to create vapor.

The vapor rises up through the packed column, making contact with the liquid phase as it passes through the packing material. The vapor contains a mixture of different compounds with varying boiling points.

As the vapor ascends, the compounds with lower boiling points start to condense on the packing material. These condensed components return to the liquid phase.

The remaining vapor, now enriched in the components with higher boiling points, continues to rise.

At the top of the column, the vapor enters the condenser, where it is cooled and condensed back into a liquid phase. This process is facilitated by a coolant (usually water) circulating through the condenser’s coils.

The condensed liquid collected at the bottom of the condenser can be collected and is often referred to as the distillate or product.

The packed column with a condenser is an efficient setup for separating and purifying mixtures in various industries, including petrochemical, pharmaceutical, and food processing. The specific design and operation of such systems can vary based on the specific process and the properties of the substances being separated.

| Language | English |

| Drawing Type | Detail |

| Category | Drawing with Autocad |

| Additional Screenshots | |

| File Type | dwg |

| Materials | Steel |

| Measurement Units | |

| Footprint Area | |

| Building Features | |

| Tags | packed column, packed column with condenser, packed column with separator |