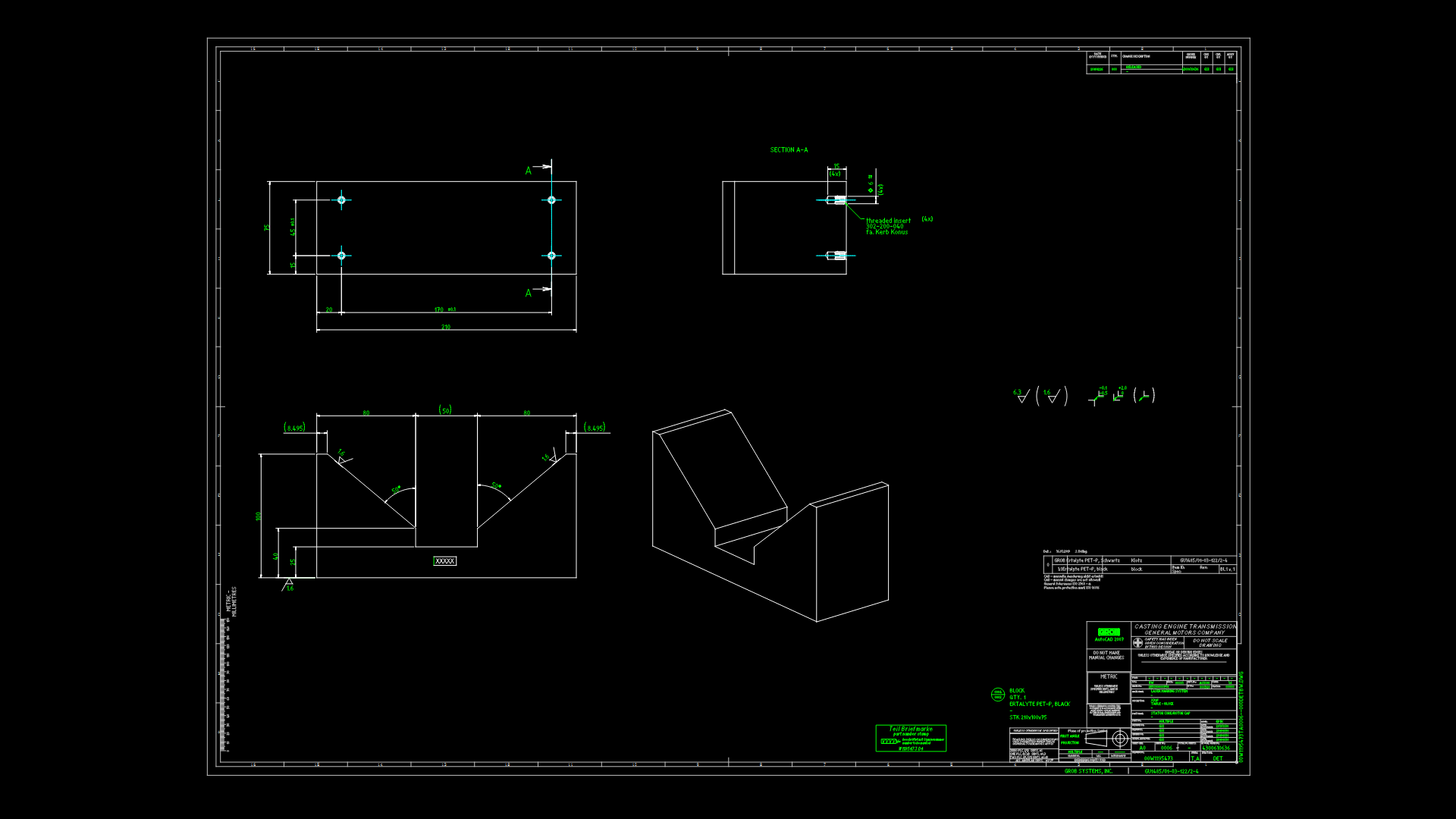

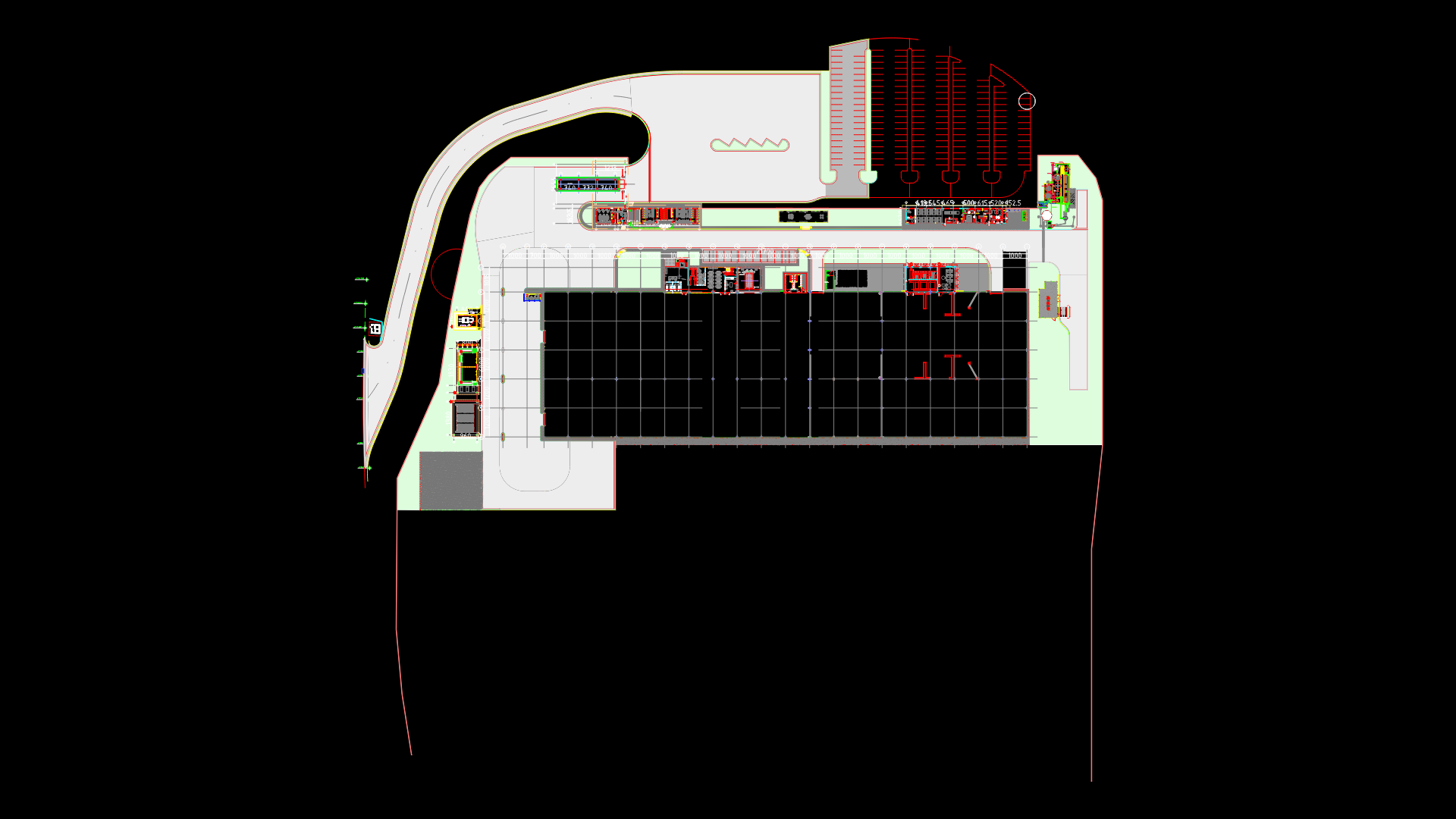

Containers – Separators DWG Block for AutoCAD

Horizontal 2-phase separator – Separator Vertical 2-phase – 3-phase separator Horizontal – Vertical Separator 3 phase – arrest procedure separator – separator control Tipico

Drawing labels, details, and other text information extracted from the CAD file (Translated from Spanish):

Inlet, oil outlet, water outlet, water chamber, gas, oil, water, well current, most of the liquid section is filled with oil, level to the midpoint in the vessel, gas outlet, outlet liquid, drainage, venting, safety valve, typical separator control, level controller, routine operation verification, pressure controller, separator stop procedure, input current, separator start procedure, section separate steam, water inlet, water outlet and sand, injection nozzle, sand cone, pressure control, interface, oil-water, oil chamber, bucket, landfill, water-oil interface, level controller, mixing oil-water, centrifugal element, mister mesh, liquid level center, interconnection, inlet chamber, recirculation line, connection, pneumatics, filtering elements, gas inlet, coalescer plates, horizontal baffle, vortex breaker e, deflector plate, aligned vanes, water level, interface level, oil level, interface, garbage layer, when a level window is connected in a garbage layer, the level window can be completely filled with garbage and there is no oil-water interface visible., the liquid in the level window is oil and clean water. the garbage layer in the separator is not shown in the level window, clean gas outlet, quick opening and closing lid, float protector, liquid chamber, packing section with hay or excelsior, separation process, the droplets of liquid in the gas must be separated before the gas leaves the container, the gas bubbles in the liquid must be broken before the liquid leaves the container, the decanted liquid section, procedure for dimensioning a separator, flow of gas and liquid in the separators, adjustment of the pressure controller, close the valve in the liquid outlet line, when the liquid level is normal, open the valve in the liquid outlet line and put into service in the controller level, llsl, deactivate the permissive for low level if the level is low, check the output lines to see that there is flow of gas and liquid according to the appropriate situation, slowly open the valve to enter Open the valve in the inlet line, open the valve in the vent line to depressurize, if the container should be depressurized, close the valve in the gas line, close the valve in the liquid line if not required draining, if the container should be drained, there will be the by-pass valve or adjust the controller to drain the liquid. Then close the valve in the liquid line, pdi, check if there is an increase in pressure by the coalescing devices, check the valve stroke, clean the level sight glass, verify the proper reading of the instrument, the pressure controller should hold a constant pressure by the gas flow control valve, the level controller must hold a constant level by the liquid flow control valve, initial flow, the water level is increased to provide more volume decanted water, flow five years later, a low level in the water compartment results in a low level of interface, which provides a high volume of decanted oil and a low volume of decanted water., a high level in the water compartment results in a high level of interface, which provides a low volume of decanted oil and a high volume of water decanted., interconnection, liquid chamber, recirculation line, drain, plate s coalescers

Raw text data extracted from CAD file:

| Language | Spanish |

| Drawing Type | Block |

| Category | Industrial |

| Additional Screenshots |

|

| File Type | dwg |

| Materials | Glass, Other |

| Measurement Units | Metric |

| Footprint Area | |

| Building Features | |

| Tags | à gaz, agua, autocad, block, containers, DWG, gas, híbrido, horizontal, hybrid, hybrides, l'eau, phase, reservoir, separator, tank, tanque, vertical, wasser, water |